Are excessive warranty headaches calling for a breakup with your supplier?

Stellana wheels are used throughout several industries. In all cases, our wheels serve as a piece to a greater assembly. Our parts often provide mobility or movement to the equipment they accompany. When a wheel fails in production or the field, the structure cannot function as intended, and the customer file warranty claim. Frequent failure and warranty issues play a significant role in the buyer’s decision to choose a new supplier.

Many of our customers have chosen Stellana as a supplier to escape their warranty issues. In one specific instance, we have sent a scissor lift manufacturer over 13,000 parts – many of which have been in use for several years. To date, the Stellana components that the customer has received have resulted in zero warranty claims – and this is a realistic expectation for your supplier. The elimination of warranty has greatly reduced their costs. Overabundant warranty claims should not be a part of your supplier relationship.

Why are frequent claims a problem?

You may be thinking to yourself, isn’t a product warranty a good thing? The quick answer would be yes. As a consumer, you want to have confidence in the integrity of your product and assurance that the manufacturer will take care of you in the event of defects or product failure, but there is more to it.

Think about the situation like the auto insurance you carry, as the consumer, you must have a policy in place, and you would like the best coverage, but you would also prefer not to have to use it. Beyond the priority of yours and other’s safety when operating a vehicle, higher premiums, difficulty obtaining coverage, and the loss of bonuses incentivize you to minimize the claims you’re making.

Similarly, when buying polyurethane wheels, the purchaser wants an understanding that the manufacturer that will stand behind their product but having to claim warranty can be costly and time-consuming for all parties involved. The preferred outcome is to receive a working, consistent product from the supplier time after time.

A Typical Warranty Procedure

Our polyurethane wheel and tire systems are never stand-alone. For example, the production of particular lift trucks includes incorporating a Stellana drive tire. Likewise, our tires and wheels are sold to service providers as replacements parts when the machinery has been purchased and is in use. For that reason, warranty claims on Stellana parts can be filed both during the buyer’s production of their equipment or when the wheels are in use in the field.

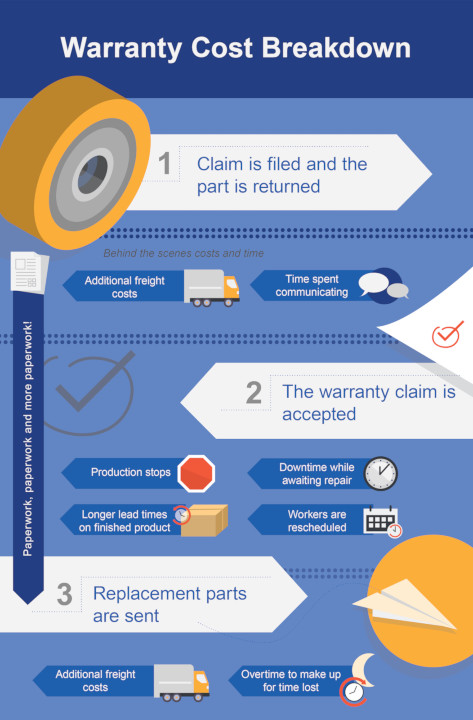

Once the customer files a claim, the paperwork begins, and plenty of back and forth takes place between the manufacturer, dealer, and consumer. Let’s take a quick look into a typical series of events in this situation.

- First, the customer files the claim and returns the defective parts to the manufacturer. This step is the start of the necessary paperwork.

- If applicable, the claim is then accepted by the manufacturer to proceed, and both parties complete the required documentation.

- Replacement parts will be made and sent once a claim is accepted. All parties finalize their paperwork.

These three steps may sound relatively simple, but don’t let that fool you. Faulty parts require a tedious process with many complications behind the scenes. Between these steps, costs continue to increase. If an OEM purchased the wheel for their production, they are forced to shut down this line until there is an acceptable part to use, which results in extended lead times. Workers on these lines are rescheduled and forced to work overtime when the replacement parts are received to counter the effects of halted production.

When wheels fail in the field, operators experience lost time during the wait for a costly service call. You also endure lost time when the equipment cannot be out running as intended. The lost time from the repair can once again lead to overtime. Also, the shipments required to return defective parts and supply new parts lead to extra freight costs.

Beyond these more tangible costs, soft costs also rise to account for a hefty portion of the total costs. Paperwork accounts for most of the soft costs. The end-user, dealer or OEM, and manufacturer all have the documentation they are responsible for completing. Whether it is filling out warranty paperwork, creating new orders, rescheduling shipments, or production – there is much time spent on documentation and communication between all parties.

Every step of the process loses efficiency, and the effects trickle down throughout each level involved. The lost efficiency translates to increased costs for the manufacturer, ultimately making the parts more expensive.

Expect More from Your Supplier

Frequent warranty claims should not be a part of your normal operations. Tightly controlled processes are the key to eliminating warranty. Beyond that, understanding the root cause of failure is also important. Many warranty issues can be tied to product misuse and application errors.

As a supplier, we do more than manufacture polyurethane parts. Our interest in providing the highest-quality, application-based solutions keeps our claims low and our customers happy. We are always grateful to hear when our wheels offer the consistency and longevity our customers expect!

About Stellana

Stellana US is a world-class manufacturer of solution-oriented polyurethane wheels, tires, and custom parts. Stellana provides solutions for several industries, including material handling, automation technology, construction, and more!