Poly What?

Polyurethane; a material we have all heard of in the material handling industry, but what do we really know about it? In the following, the history of polyurethane and its uses in the material handling industry and other areas will be explored.

History

Polyurethanes were invented in the 1930’s by Professor Dr. Otto Bayer as a much needed replacement for rubber in World War II. Alongside replacing rubber, polyurethane coatings were used for the impregnation of paper and the manufacturing of mustard gas resistant garments, high-gloss airplane finishes, and chemical & corrosion-resistant coatings to protect metal, wood, and masonry.

After the war, polyurethane began to expand to a much larger scale. It started expanding through industrial applications, such as coatings. Today, polyurethane can be found it almost every material.

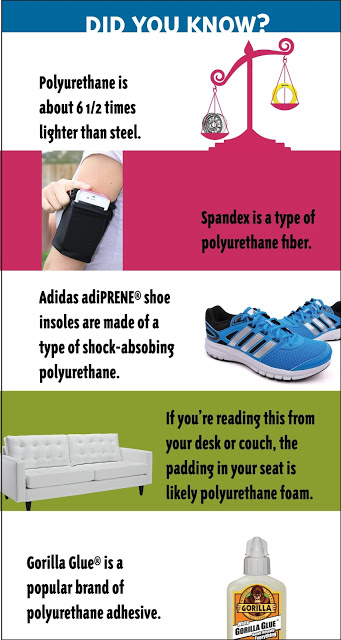

Polyurethane in Everyday Applications

- Polyurethane applications include, but are not limited to:

- Thread in apparel

- Rigid foams for refrigerators & freezer thermal insulation systems

- Car seats

- Foam padding in carpet

- Composite wood

- Boat hulls

- Medical tubing & wound dressings

For more applications, check out this list from the American Chemistry Council.

Polyurethane in the Material Handling Industry

Since the chemistry of polyurethane can be adjusted to highlight selected material properties for the application, polyurethane can be found in the material handling industry in a variety of ways. Polyurethane can be as flexible as a rubber band or as rigid as some metals, but no matter what the scenario polyurethanes are admired for their durability, chemical & water resistance, and resilience. For more information on how different polyurethanes are made, watch this video.

Some examples of polyurethane in the material handling industry include:

- Wheels

- Tires

- Gears

- Sprockets

- Flooring

- Packaging

- Rollers

- Conveyor belts

At all Stellana locations, we make parts with hot cast polyurethanes. Hot cast polyurethanes are solid, durable materials that can be formulated into a machinable product for wheels and tires with the best load bearing capabilities, cut and tear resistance, low heat build-up, and abrasion resistance. These polyurethanes are also non-marking, lightweight compared to metal alternatives, and carry heavier loads than rubber tires (up to 4x more!). The durometer of our tires range from 70A to 100A.

Additional features include:

- Tread treatments (optional)

- Custom colors

- Water resistance

- Low temperature flexibility (cold storage applications)

- Oil resistance

Stellana US is a proud member of the Polyurethane Manufacturer’s Association. Read more about cast polyurethane industry here: http://www.pmahome.org/main/polyurethane101/.

Additional Resources

https://polyurethane.americanchemistry.com/History/

http://polyurethanes.org/en/what-is-it/history